Selecting the Top Foundry for Machining Projects

Professional Machining & Machine Shop Capabilities for Custom Industrial Parts

Professional machining and machine shop services are essential to the production of custom industrial pieces. These services cater to multiple industries, ensuring accuracy and excellence in every piece. Skilled machinists utilize advanced processes to meet specific project specifications. Understanding the intricacies of these processes can significantly influence product results. As industries evolve, so too do the technologies that drive these solutions. What does this mean for future manufacturing processes?

Primary Advantages of Custom Machined Parts Across Various Sectors

Although mass-produced components have their place, custom machined parts present notable advantages that can considerably enhance numerous industries. One of the main benefits is precision; custom machining enables exact specifications tailored to specific applications, guaranteeing peak performance. This level of accuracy lessens the likelihood of errors and lessens the need for adjustments during assembly.

Moreover, custom machined parts allow for greater material versatility, allowing engineers to choose suitable materials depending on the environmental conditions and performance requirements. This adaptability can substantially enhance the longevity and durability of components.

Additionally, custom solutions can foster innovation, as distinctive designs can produce enhanced functionality and efficiency. In sectors such as aerospace, automotive, and medical, where performance is vital, these strengths become indispensable. Eventually, the ability to create specialized parts results in improved productivity and competitiveness in multiple industries.

What Is Professional Machining and Machine Shop Operations?

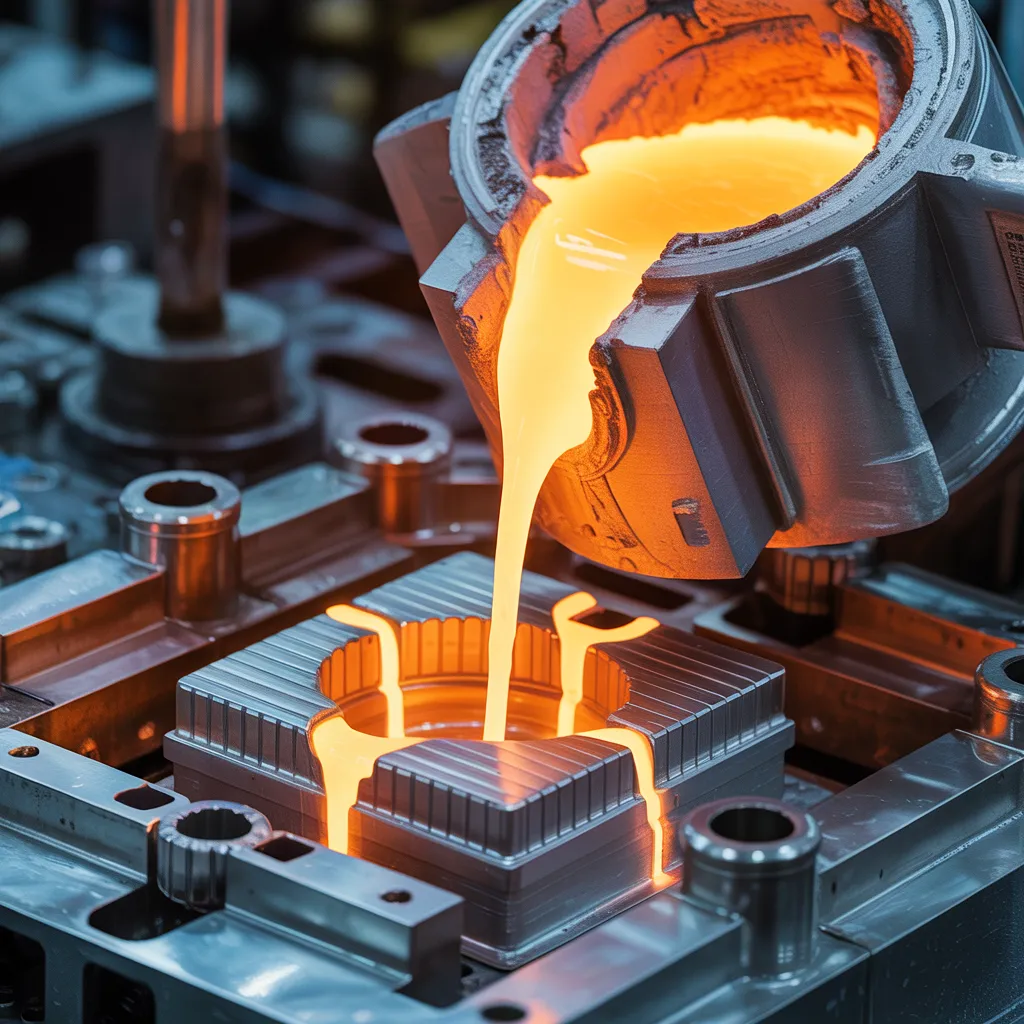

Professional machining and machine shop services offer a thorough range of services customized to fulfill the demands of diverse industries. These solutions include an array of processes, including precision machining, CNC machining, milling, turning, and grinding, facilitating the production of intricate and precise components. Experienced machinists use state-of-the-art technology and equipment to guarantee accuracy and efficiency in fabricating custom parts.

Moreover, expert machining services often include design consultation, prototyping, and quality assurance, guaranteeing that the final products satisfy stringent specifications and industry standards. With capabilities to work with a extensive variety of materials, from metals to plastics, these machine shop solutions cater to sectors such as aerospace, automotive, medical, and energy. By leveraging proficiency in machining techniques and industry know-how, these service providers help organizations achieve their production goals while maintaining top-tier outcomes.

Selecting the Right Machining Partner: Key Factors to Consider

Upon selecting the ideal machining partner, what key factors should be taken into account? First and foremost, the partner's skill and experience in the pertinent industry must be examined. This includes examining their understanding of specific materials and processes pertinent to the project. Moreover, the machining capabilities should align with project requirements, such as precision, complexity, and volume.

Another crucial element is the quality assurance processes in place. A reputable partner will have solid quality control measures to confirm that all parts meet industry standards. Customer service and communication are of equal significance, as a collaborative relationship can enable smoother project execution.

Last but not least, it's important to consider cost-effectiveness, balancing quality alongside budget restrictions. A detailed analysis of prospective partners according to these elements can lead to a fruitful collaboration, ultimately producing high-quality custom parts that fulfill or go beyond expectations.

How New Technologies Are Changing Machining Services

Developments in technology are notably transforming machining services, enhancing efficiency and precision in the production of custom parts. The integration of computer numerical control (CNC) machines facilitates automated and highly precise operations, reducing human error and boosting output consistency. In addition, the adoption of additive manufacturing technologies facilitates complex geometries to be created with minimal waste, thus promoting sustainability.

Software innovations, such as CAD and CAM, facilitate superior design and simulation processes, permitting engineers to conceptualize and test components ahead of physical production. Moreover, real-time data analytics and IoT connectivity optimize monitoring and maintenance, resulting in reduced downtime and improved production schedules.

Such technological advancements not only streamline workflows but also allow machine shops to react more quickly to market demands. As a result, companies can present bespoke solutions while upholding competitive pricing and shorter lead times, ultimately reshaping the landscape of machining related resource services.

Managing the Journey: From Sample Design to Large-Scale Manufacturing

Although transitioning from prototype to comprehensive production can be challenging, a clearly defined process can streamline this journey. To begin with, clear specifications and design documentation are vital, ensuring that all stakeholders recognize the project requirements. After this, a comprehensive evaluation of production potential, materials, and technology must be conducted to establish the most optimal methods.

Next, a pilot run is often executed to evaluate the manufacturing process, enabling the identification of potential issues before full-scale production starts. During this phase, collaboration between engineers and production teams helps to refine techniques for efficiency and quality assurance.

When pilot validation is complete, scaling up production requires careful planning, involving allocation of resources and management of timelines. Regular monitoring and feedback systems will aid in preserve quality and adjust to any unpredicted difficulties. By adhering to these steps, businesses can effectively shift from prototypes to complete production, securing both product integrity and operational efficiency.

Popular Questions

Which Material Options Are Available for Custom Machined Parts?

Various materials can be utilized for custom machined parts, including aluminum, steel, titanium, brass, and plastics. The decision depends on factors for example strength, weight, corrosion resistance, and the specific application specifications.

How Do I Maintain Design Accuracy in My Specifications?

To guarantee design accuracy in specifications, one should employ precise measurement tools, create in-depth drawings, engage in rigorous reviews, and collaborate with experienced engineers. Regular feedback and iterative prototyping can also enhance overall precision and reliability.

What's the Average Turnaround Time for Custom Machining Projects?

Average turnaround time for custom machining projects differs, commonly ranging from a few days to multiple weeks. Elements determining this include the complexity of the project, materials availability, and the shop's current workload, influencing overall production schedules.

Do Minimum Order Quantities Exist for Custom Machined Parts?

Usually, custom machined parts come with minimum order quantities, which can differ in relation to the technical demands, material, and machining processes involved. These requirements guarantee effective production and cost-effectiveness for both the manufacturer and the client.

How Should I Maintain My Custom Machined Parts After Production?

For maintaining custom machined parts after production, regular cleaning, lubrication, and inspection for wear are vital. In addition, storing parts in a controlled environment can inhibit corrosion and prolong their operational lifespan substantially.